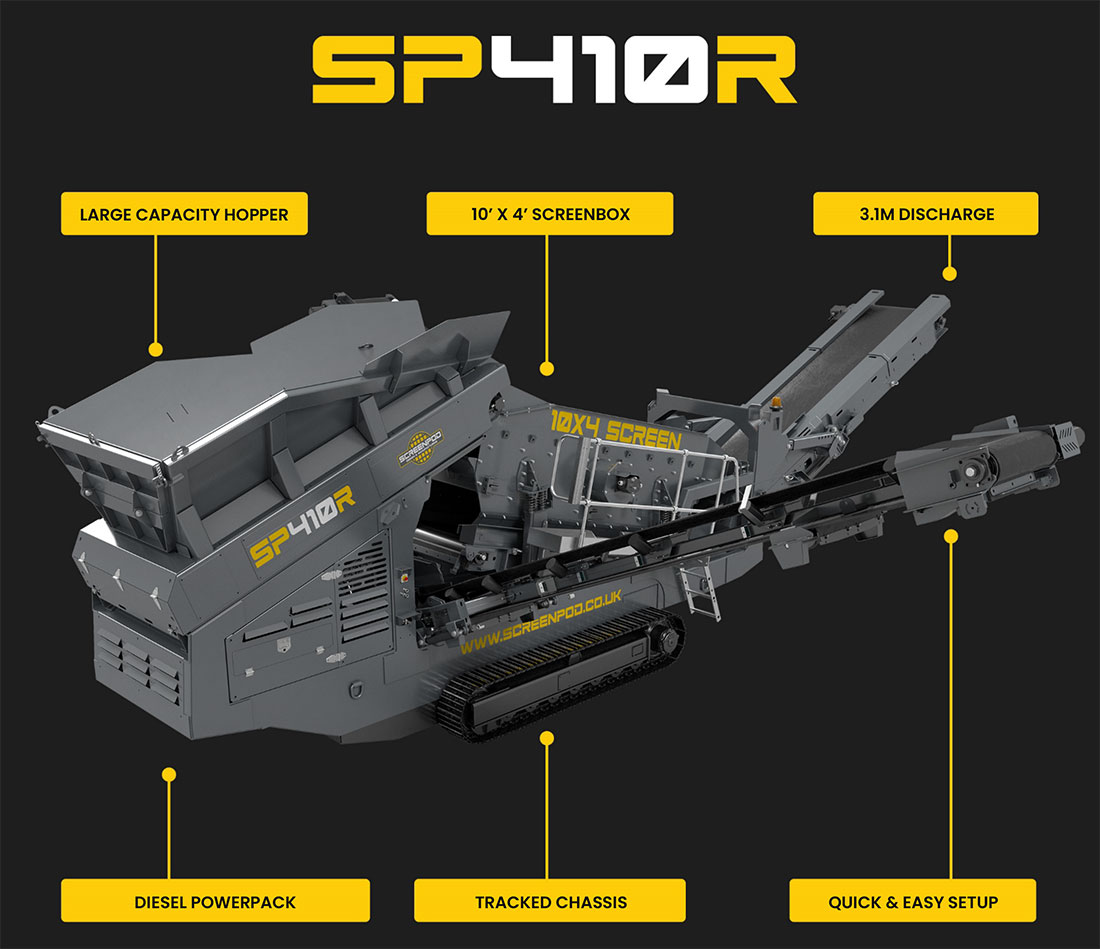

SP410R Scalping Screener

The Screenpod SP410R Scalping Screener is designed to efficiently separate and size materials in a variety of applications.

Equipped with adjustable screens, it effectively removes large debris, fines, and oversized material, ensuring smooth material flow and improved processing efficiency.

Ideal for use in industries such as construction, mining, and aggregate production, the SP410R offers robust performance and versatility, making it an essential tool for pre-screening and material sorting before further processing.

Features & Benefits:

- TIER 3 – T.DEUTZ 2011 or JCB444 DIESELMAX – ROW

- TIER 4F – JCB444 ECOMAX IPU OR STAGE 5 CAT – USA

- STAGE 5 – T.DEUTZ 2.9 L4 / CAT / JCB444 DIESELMAX – EU

- HIGH ENERGY 3M X 1.2M (10’ X 4’) 2 BEARING SCREEN BOX – 2 DECKS

- VARIABLE SPEED CONTROL ON ALL BELTS (EXCLUDING FINES COLLECTION CONVEYOR)

- FLIP DOWN HOPPER TAILGATE TO ALLOW DIRECT FEED FROM A CRUSHER BELT

- TAIL CONVEYOR LOWERS HYDRAULICALLY TO ALLOW ACCESS TO

- BOTTOM SCREEN DECK

- HYDRAULIC FOLDING TAIL CONVEYORS

- FIXED SCREEN ANGLE AT 15º

- SIDE TENSIONED TOP DECK. END TENSIONED BOTTOM DECK

- EASY ACCESS TO ENGINE COMPARTMENT

- CONTAINERISES WITHOUT ANY BREAKDOWN

Options:

- SCREEN DECKS – MESH, BOFAR BAR, FINGER SCREENS OR PUNCH PLATES.

- RADIO REMOTE CONTROL

- OVERBAND MAGNET ON OVERSIZE CONVEYOR

Weight:

- 15,600 KG

Scalping Screens Range

SP514R Scalping Screener

Scalping Screens

SPG100 Scalping Screener

Scalping Screens

SP410R Scalping Screener

Scalping Screens