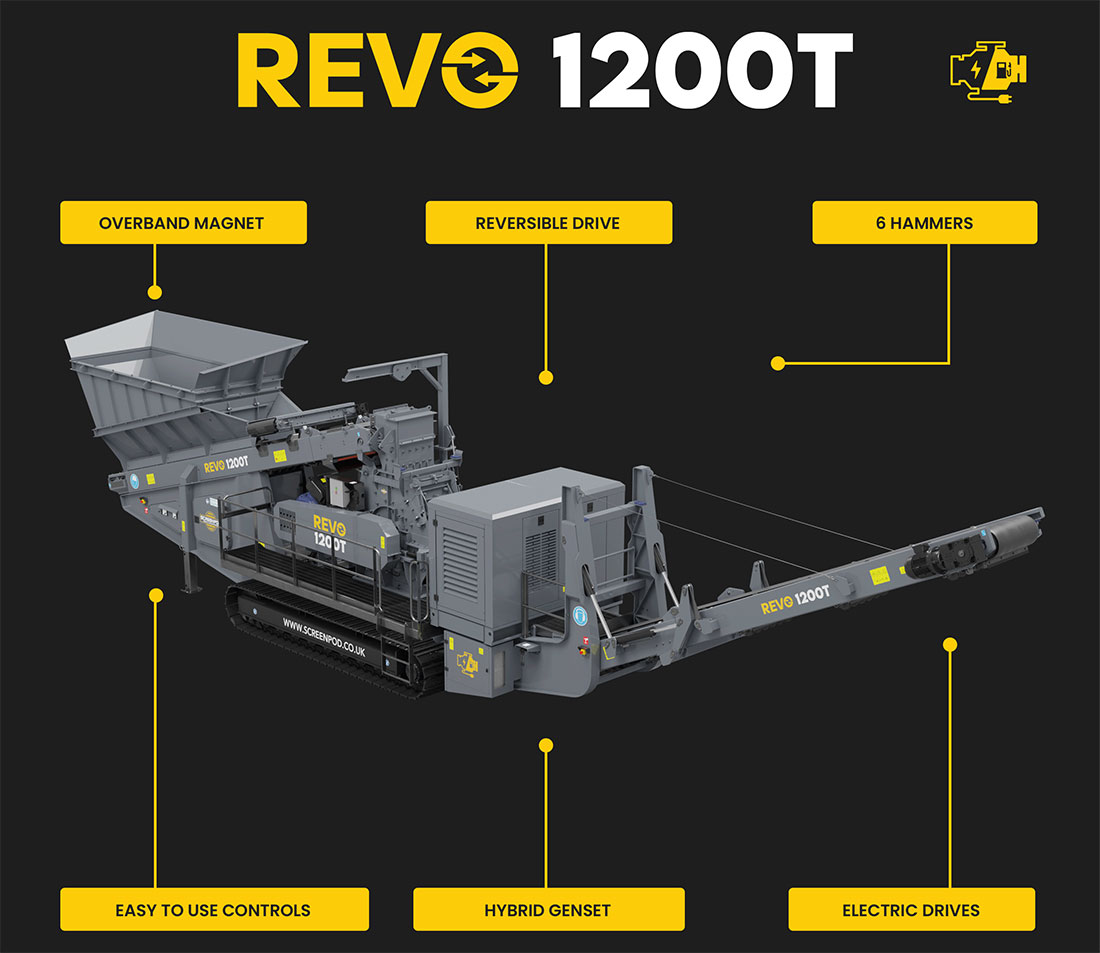

REVO 1200T

Introducing a ground-breaking and revolutionary mobile crushing solution, The Screenpod REVO 1200T Reversible Impact Crusher. The newly developed tracked mounted impact crusher is a versatile and unique Hybrid crusher that adapts effortlessly to diverse job site conditions, offering an innovative blend of efficiency and flexibility. The Screenpod REVO 1200T Reversible Impact Crusher is pioneering an exceptional concept in aggregate processing technology.

It is engineered to operate either on its own genset or connected to an external power supply which is built for ultimate convenience and seamless integration into any crushing operation with flexibility in the secondary and tertiary crushing of rock and recycling building materials.

Design features include a 6-hammer reversible rotor that moves bi-directionally within the chamber. This unique feature helps maintain consistent geometry from the hammer to the 9 impact bars as they wear, maximising throughput consistency and performance, whilst also ensuring even wear across blow bars. As a result, this significantly extends service life. This system offers better quality of the end products i.e. grain shape and significant energy savings particularly in sand production (0/4mm: approximately). This makes this highly mobile solution, an excellent alternative to Cone Crushers and VSI Vertical Shaft Impactors as the maximum feed size is up to

120mm.

Applications

With its customisable crushing gap and VSD control, the Screenpod Revo 1200T provides precise control over material size and consistency of finished product, catering to a wide range of applications. Applications Include:

- Aggregates

- Oversized gravel

- Asphalt

- Concrete

- Construction

- Demolition waste

- Glass Recycling

- Aerated Concrete

- Natural Rock

- Sand

- Stone

Features & Benefits:

- Hybrid – Diesel or Electric power

- 302 hp / 225kW Cummins Turbocharged engine

- Electric Drive Feed & Product Conveyors

- Reversible Crusher Unit

- Control panel with user friendly interface for straightforward operation

- Emergency stops located around periphery of machine for shut down

- Access doors and removable panels for maintenance

- Metal Detector

- Overband Magnet

- 800mm (32”) wide variable speed Feed and Product Conveyors

- Impact Hopper

Options:

- 4″ (90mm) Tipping Grid with Remote Control no shroud

- Scales

- Autolube

- Emergency Pull Wires (2 conveyors)

- Discharge Conveyor Head Chute & Rubber Sock

- Working Lights

- Dust Suppression: 3 x Bars & Manifold & 24V Water Pump & Filter Upgrade